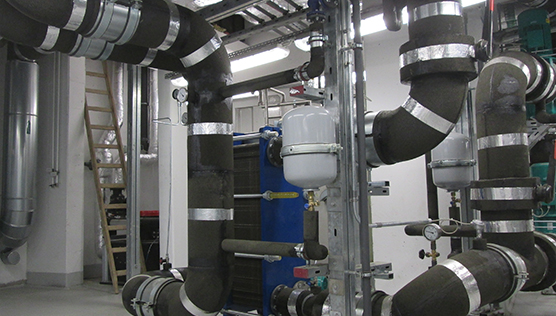

SUPPLY & INSTALLATION OF NEW CHILLERS & MAINTENANCE WORKS

Supply installation and maintenance of all kinds of chillers We provide Mechanical and Electrical services to commercial, retail, residential segments. Whatever your MEP requirement, we are sure of rendering a solution tailored to you. As experts in our field, we are able to offer our valuable insight into all aspects of your demand. Our specialty is in Designing, supply and installation of Chillers AHIJ and FCU Services and Maintenance. We offer specialized skills of our experienced team, consisting of factory certified technicians by all key chiller manufacturers such as Bitzer, York, Carrier, Trane, etc including All kinds of maintenance and installation for FAHU, AHU, FCU, package units, split AC units and Ductable Split AC Units.

Leak testing, repair C containment systems. Component replacement. Refrigeration C electrical systems, compressor replacement compressor overhaul, oil and filters, controls and switchgear etc.

- Pressure relief valve replacement programmes and modification.

- Condenser chemical cleaning, repair, replacement.

- Engineered refrigerant conversion programmes.

- Eddy current testing.

- Dilapidation reporting and remedial works programming.

- Refrigerant recovery and disposal.

- Specialist centrifugal chiller service & repair.

- Complete chiller refurbishment.

- Testing, Commissioning & De-commissioning.

- Commercial buildings use Heating, Ventilation and Air Conditioning (HVAC) systems to dehumidify

and to cool the building. Modern commercial buildings seek efficient HVAC systems and

components as part of broader initiatives centered on building performance and

sustainability. Building occupants similarly carry great expectations, that the HVAC system will

function as intended to create a comfortable interior environment regardless of the conditions

external to the building. - Chillers have become an essential HVAC component of a wide variety of commercial facilities,

including hotels, restaurants, hospitals, sporting arenas, industrial and manufacturing plants, etc. - Industrial chiller maintenance checklist

- Inspection of all water inlets and outlets for leaks should be done routinely.

- All components of the compressor unit should be inspected including checks for oil levels, leaks,

vibrations, operating temperatures variations. - Electrical contacts should be inspected and cleaned.

- Filter dryers should be checked, and dirty, old or faulty filters replaced entirely.

- Cooling coils must be inspected for distortion in fins, and signs of corrosion.

- Condenser fan inspections should be carried out with emphasis on bearings check for signs of wear,

poor lubrication. Belts and couplings should also be checked and adjusted when necessary. - Condenser coils should be inspected for leaks, corrosion, and areas of kinking or blockage.

- Fresh air dampers for an air-cooled chiller system should be inspected in the same way as return air

dampers. - Preventive Maintenance for Industrial Chillers

- Maintain your Daily Logs

- As basic as this may seem, having a daily record of operating conditions, the pressure and

temperatures in the chiller unit, as well as the fluid levels and flow rate, could help quickly predict

the likelihood of future damage to the chiller machine. Keeping a chiller log sheet is advantageous as

a pre-emptive chiller maintenance schedule can be structured before the onset of actual damages. - Make chiller preventive maintenance easy with the Cold Shot Guardian™ predictive maintenance

app. This tool helps eliminate unscheduled downtime by providing “real-time” chiller guardian app

screenshot operational information through your WIFI, LAN, or even LTE connections. - Keep the Chiller Tubing Clean

- Over time, corrosion can accumulate inside the chiller tubing and impede the removal of generated

heat. Therefore, it is necessary that regular quarterly or at least yearly cleaning of chiller tubes is

scheduled and carried out. - Maintain an Optimal Chilled Water Flow Rate

- Determining the Right Size of Chiller for Your Needs